Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

RIEGLER SAFETY

SAFETY AND ENERGY EFFICIENCY IN COMPRESSED AIR TECHNOLOGY

With our product range RIEGLER SAFETY, you make your compressed air applications safer and more efficient – and thereby even better.

PRIORITIZE SAFETY

Out of over 800,000 reported workplace accidents in Germany in 2021, approximately 80,000 can be attributed to compressed air. This relatively high number can be explained, on the one hand, by the widespread use of compressed air in almost every production facility and workshop, similar to electrical power.

On the other hand, experts regularly note that many accidents could have been prevented if compressed air systems or their individual components had been up to date and if a few, but crucial, safety aspects had been considered.

In addition to the personal suffering of the injured employees, the disregard of legal regulations regarding occupational safety results in significant costs: production downtime costs due to first aid amount to billions – and compressed air is responsible for approximately 10% of these costs!

The protection and safety of people at their workplace are important to us. Thus, safety in handling compressed air is a matter of the heart for us, and we contribute our part to reduce workplace accidents. Furthermore, it is important for us to raise awareness among users about handling compressed air, reduce downtime and prevention costs, and decrease energy consumption. We achieve this by optimizing compressed air workstations and compressed air networks in general.

The responsibility for safety in workplaces lies with the employers. They are responsible for issuing instructions for the proper handling of compressed air, as well as providing safe machines, equipment, and tools.

Don't wait for an accident to happen – prioritize safety and energy efficiency with products from the SAFETY range by RIEGLER.

Summarizing the commonly occurring hazards in handling compressed air:

- Hearing damage caused by noise generated from exhaust air from blowguns, hose couplings, and/or valves.

- The so-called whip lash effect, i.e., recoil when disconnecting single-stage coupling systems.

- In connection with the disconnection of coupling systems, there is an exhaust air noise that is not negligible. It is often so loud that it pushes the human hearing to its pain threshold.

- One of the classic dangers: Hoses lying on the ground become a daily tripping hazard.

- Very high potential dangers include bursting hose lines and exploding pressure vessels. In these situations, human life is more at risk than we might initially realize.

- Life-threatening embolisms can result from the entry of compressed air or foreign objects into open skin areas or wounds.

WHY CHOOSE PRODUCTS FROM THE RIEGLER SAFETY RANGE?

- Components for accident prevention and workplace safety

- Safe and healthy at work

- Legally prescribed products in accordance with currently applicable laws, standards, directives and regulations

- Energy-efficient components

- Reducing accidents at work and increasing occupational safety

- Expansion of expertise in the field of compressed air technology

EXCERPT FROM THE RIEGLER SAFETY PRODUCT RANGE

MAINTENANCE DEVICES

.

Maintenance devices from the SAFETY category protect man and machine from unauthorised pressures, from manipulation

and ensure compressed air quality.

.

INLINE PRESSURE REGULATOR

AND FILTER

Fixed pressure regulator and filter directly

in the line Tamper-proof integration

makes this category in SAFETY makes

this category possible for you.

.

PRESSURE GAUGES

.

Pressure gauges in safety design protect

the user and the machine from

uncontrolled leakage of the uncontrolled

escape of the medium through the sight glass.

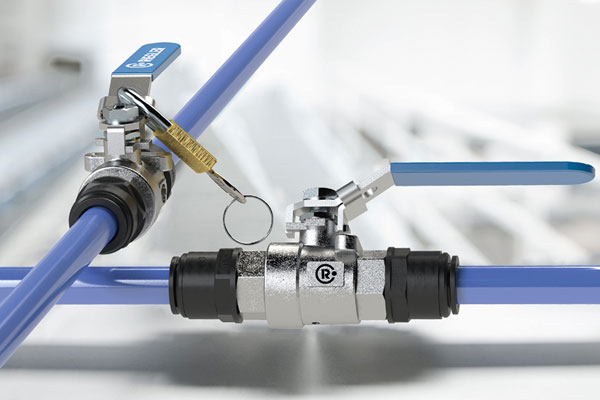

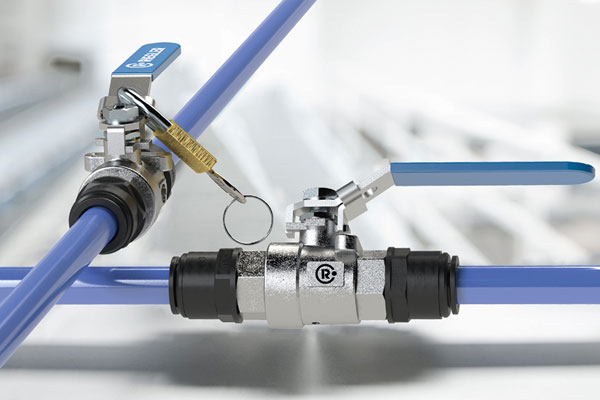

SAFETY BALL VALVES

.

Ball valves in safety design have depending

on requirements, a function for shut-off

and or a venting function for energy release

of the subsequent application.

.

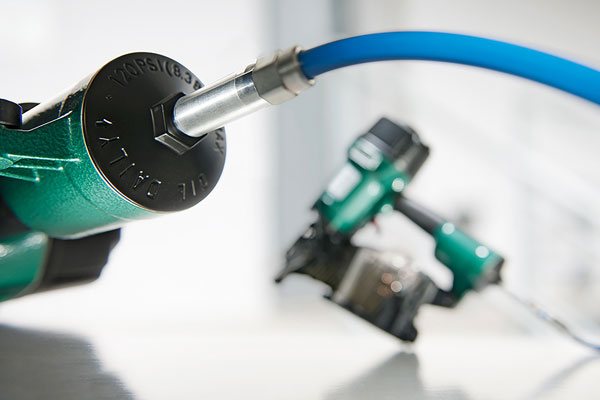

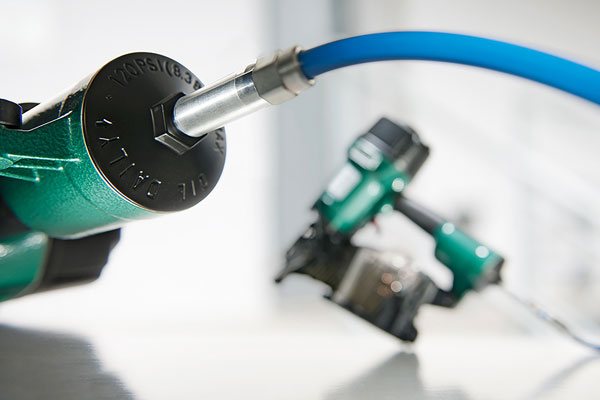

HOSE RUPTURE VALVES

.

Hose rupture valves from the SAFETY

category protect the user and machines

machines in the event of bursting or

loosening of the hose from the "whiplash effect"..

SAFETY VALVES

.

Safety valves protect secured containers

or areas from uncontrolled overpressure,

thus preventing damage caused by

excessive pressure that is not permissible

for that area or even preventing bursting.

SAFETY AND VENTING

COUPLINGS

The safety couplings included in the

SAFETY category have different protective

functions. From noise reduction to

preventing the "whiplash effect" through

to distinctiveness..

SILENCERS

.

Silencers reduce noise pollution in exhaust

applications and can therefore protect or

support the user from high noise levels.

.

.

HOSE AND CABLE REELS,

HOSE HOLDERS, HOSES

Hose and cable reels, as well as hose

holders support the user reduce

tripping hazards and ensure a tidy

working environment. Hoses in bright,

eye-catching colours can also warn of

a tripping hazard.

.

SAFETY BLOW GUNS

AND ACCESSORIES

Blow guns in the SAFETY category have

various safety features. Blow guns with

low-noise multi-channel nozzles for

almost every range of applications.

Blow guns with fixed adjustable flow rate

or baypass valve to protect the user,

when the nozzle is blocked.

AT OUR RIEGLER ACADEMY?

We are happy to support you personally. Just get in touch with us.

GET IN TOUCH

Dirk Höschle

Safety & Energy Efficiency

dirk.hoeschle(at)riegler.de

Phone: 07125 9497-458