Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Success Stories - Pneumatic Actuator For Base Valve

PNEUMATIC ACTUATOR FOR BASE VALVE

THE CHALLENGE

Tank trucks and rail tank cars transport things like chemical liquids or liquefied gases. In order to fill or empty them, high-quality, tightly closing base valves are required. For the medium in the tank to be dispensed or supplied in a controlled manner, the base valves must open reliably.

AN ADVANTAGEOUS PRICE

CUSTOMER SOLUTIONS

THE SOLUTION

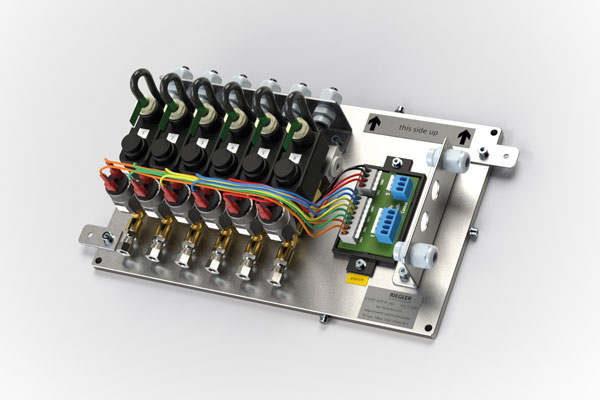

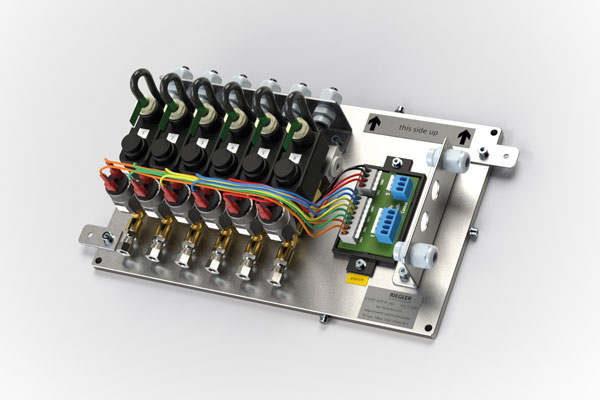

The reliable opening and closing of the base valve is performed by a pneumatic actuator developed by RIEGLER together with its customer WLS GmbH. This is activated via the compressed air system of the tank truck or tank car, whereby the cylinder is pressurized with compressed air and the piston inside starts to move. The piston rod, which is attached directly to the piston, presses on the valve seat of the base valve and opens it. A mechanical spring in the pneumatic actuator ensures that the base valve remains closed when no compressed air is applied and that none of the medium can escape. This way, the spring also ensures that the base valve closes in the event of a sudden pressure loss or line break and that none of the medium escapes into the environment. An emergency screw attached to the pneumatic actuator ensures that the base valve can also be opened manually without compressed air.

In order to meet the technical requirements at WLS, RIEGLER developed the pneumatic drive in two different housing materials: aluminum and stainless steel. The robust version made of stainless steel is used when external conditions are harsh and a high level of corrosion protection is required. The aluminum actuator, meanwhile, is the lighter and more cost-effective variant, provided that the external conditions allow it.

The solution developed by RIEGLER did not yet exist in this form on the market, as previously known actuators work as diaphragm cylinders rather than as piston cylinders. WLS received both the CAD data produced by RIEGLER and a product sample for approval in advance.

This project illustrates once again the versatility of compressed air and the multitude of different applications served by products from compressed air technology and pneumatics.

Technical data for the actuator

Working pressure max.: 10 bar

Piston diameter: 125 mm

Cylinder stroke: 32 mm

Use at ambient temperatures: – 40 °C to 50 °C

Weight: 14.3 kg (stainless steel version) / 7.8 kg (aluminum version)

WLS GmbH in Moers is active in the area of replacement parts for freight cars and locomotives. The company also maintains a focus on fittings for compressed gas as well as mineral oil and chemical rail tank cars.

The trade in rail car and locomotive spare parts is an important pillar for the company. WLS GmbH keeps an extensive range of assemblies, rail car fittings, wear-and-tear parts, and refurbished replacement parts in stock and thus acts as a just-in-time supplier for its customers.

Are you interested in a similar solution for your company? Contact us without obligation.

GET IN TOUCH

Andreas Wilkenloh

Field Service

andreas.wilkenloh(at)riegler.de

Phone: 0151 15058837

DISCOVER MORE SUCCESS STORIES

![]()

MANIPULATION-PROOF CONTROL BOX FOR GAS TANKERS – PATENTED

Oil companies and forwarding agents frequently face the following problem: Products such as fuels and heating oil that are being transported in a tanker do not arrive at the gas station...

![]()

HOSE ASSEMBLIES FOR ALGAE CULTIVATION

Microorganisms (algae) are becoming increasingly important in industries such as food, pharma, and medicine. Algae are also being used, for example as a food source for astronauts...

![]()

ASSEMBLIES FOR COMPRESSED AIR DISTRIBUTION

Batch mixing plants are ideally suited for production of suspensions containing solids, mixtures that are overall made up of several solid and liquid components as well as a...

![]()

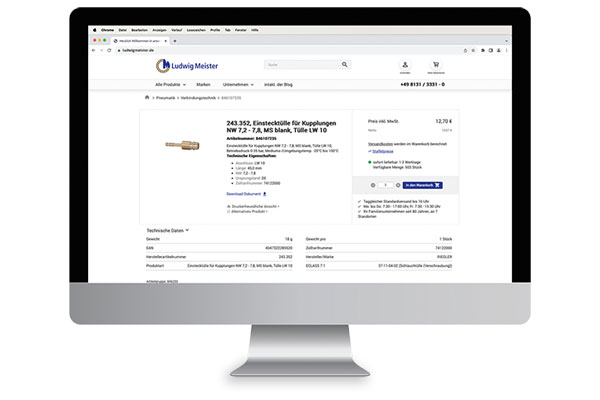

HIGH-GRADE MASTER DATA TO BOOST SUCCESS

Technical retailers face the challenge of designing efficient processes in order to keep pace with the competition. Absolutely accurate master data are crucially important...