Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Metering and Lubrication Technology

METERING AND LUBRICATION TECHNOLOGY

The use of compressed air in metering and lubrication technology enables precise and controlled processes, which are applied in various industries such as the automotive industry, electronics manufacturing, food processing, and many other applications.

COMPRESSED AIR TECHNOLOGY IN METERING AND LUBRICATION TECHNOLOGY

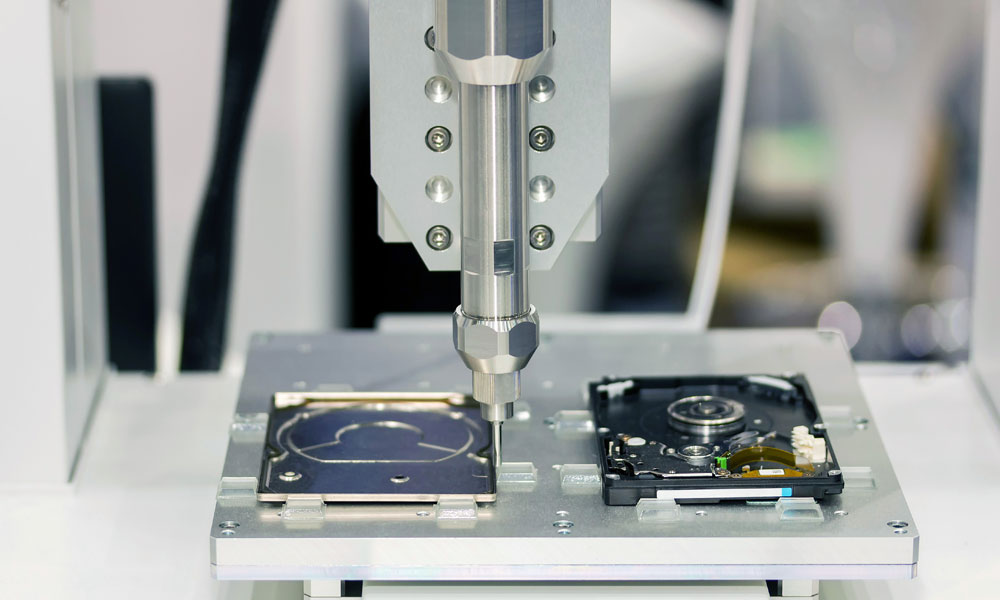

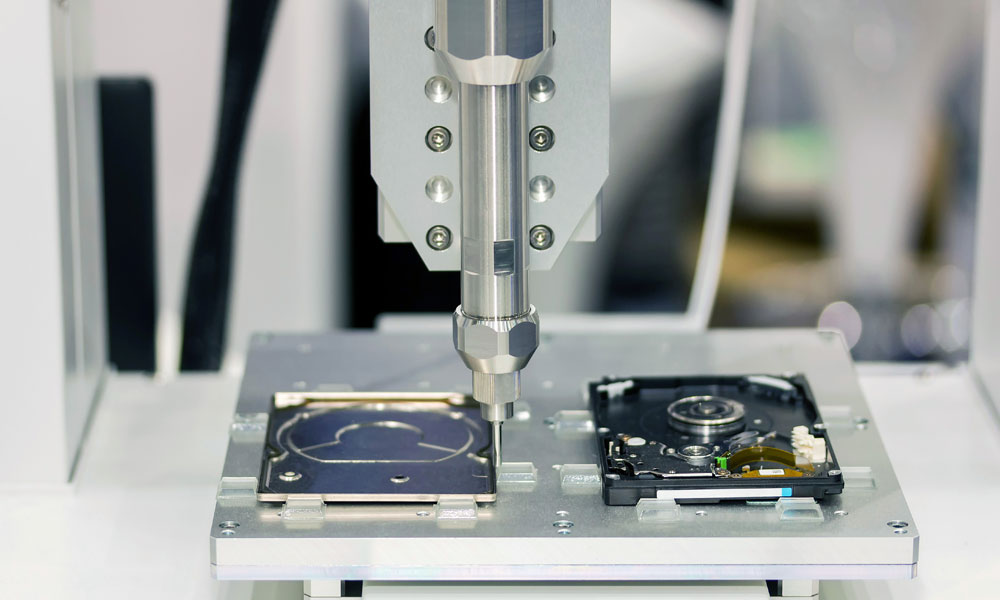

In many industrial processes, it is necessary to meter specific liquids or pastes in precise quantities. These materials are conveyed and metered in the desired quantity with the help of compressed air through valves or nozzles.

Compressed air can be utilized to mix liquids or pastes by blending and homogenizing them. This is particularly crucial in processes where an even distribution of various components is required.

In lubrication technology, compressed air can be employed to apply lubricants to moving parts or machine components. This ensures an even distribution of the lubricant and can extend the lifespan of machines and equipment.

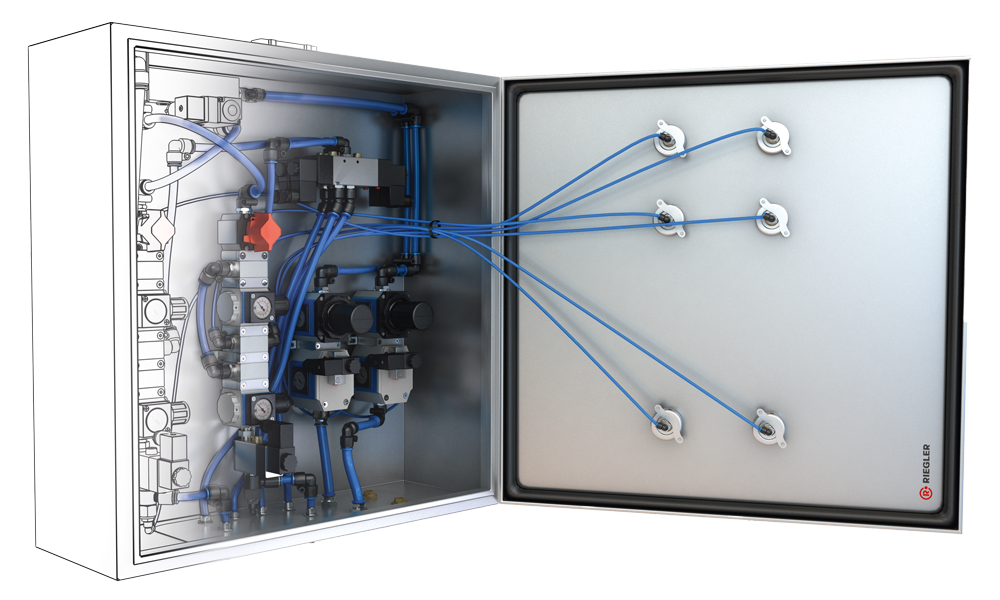

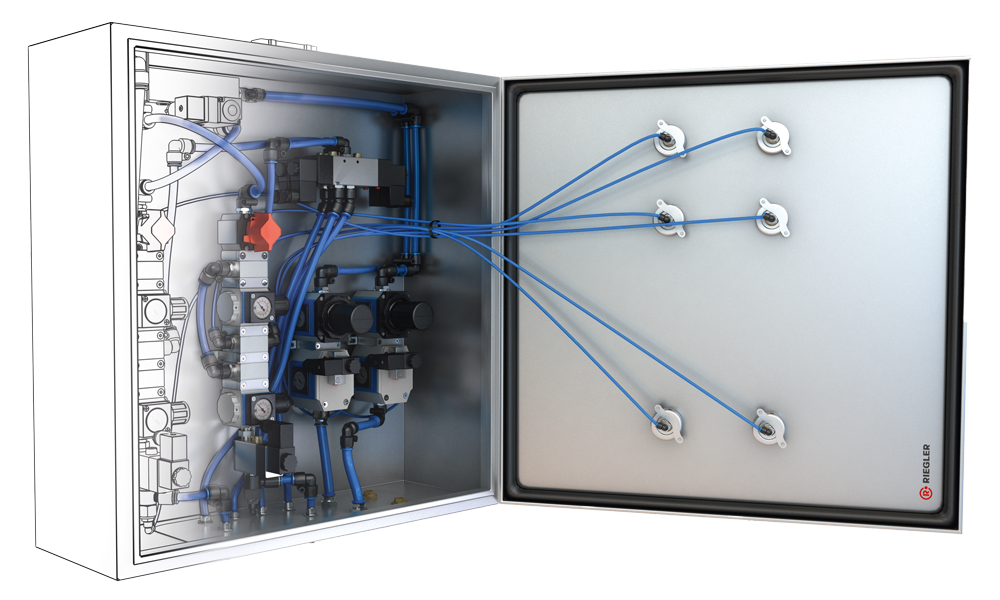

PNEUMATIC CONTROL CABINETS

Electro-pneumatic controls for a drum pump system for conveying adhesives.

- Central electrical connection via Harting plug

- Immediately connectable and ready for use

- Dual pressure display (internal and externally routed)

The control unit is designed for air supply including drum ventilation function. All pressures are preset via pressure regulators in the control cabinet and displayed internally and externally via pressure gauges.

Are you interested in a solution for your company?

GET IN TOUCH

Technical services

engineering(at)riegler.de

Phone: 07125 9497-642