Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Construction Vehicle Manufacturing

COMPRESSED AIR TECHNOLOGY IN CONSTRUCTION VEHICLE MANUFACTURING

Construction vehicle manufacturing is a specialized area within vehicle construction that focuses on the development, design, and production of a variety of vehicle types and machinery for the construction industry. These vehicles and machinery are specifically designed for use on construction sites and are tailored to handle a wide range of tasks in construction and building sectors.

COMPRESSED AIR TECHNOLOGY IN CONSTRUCTION VEHICLE MANUFACTURING?

Compressed air technology in construction vehicle manufacturing encompasses various products. Compressed air serves as a versatile energy source, finding applications in different functions and operations within the construction industry. Here are some examples of compressed air technology products used in construction vehicle manufacturing:

- Air compressors

- Pneumatic brakes

- Pneumatic lifting and tipping devices

- Pneumatic tire pressure regulation systems

- Pneumatic suspension systems

- Pneumatic drilling rigs

- Pneumatic dust removal systems

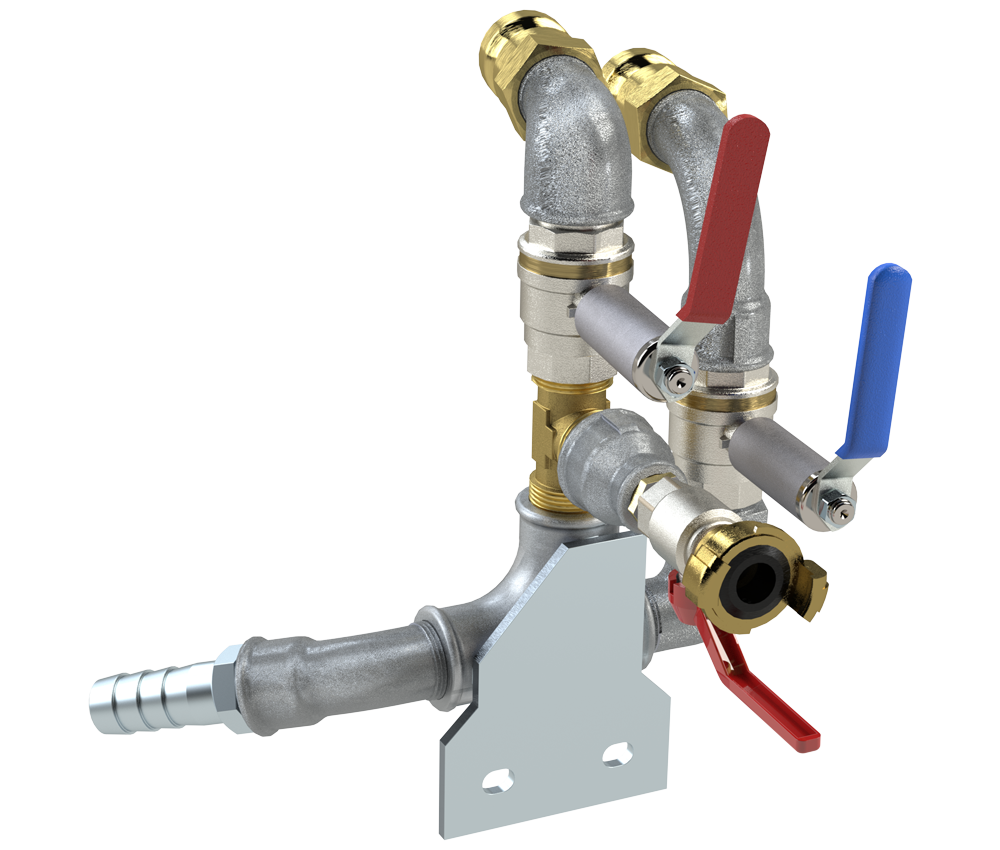

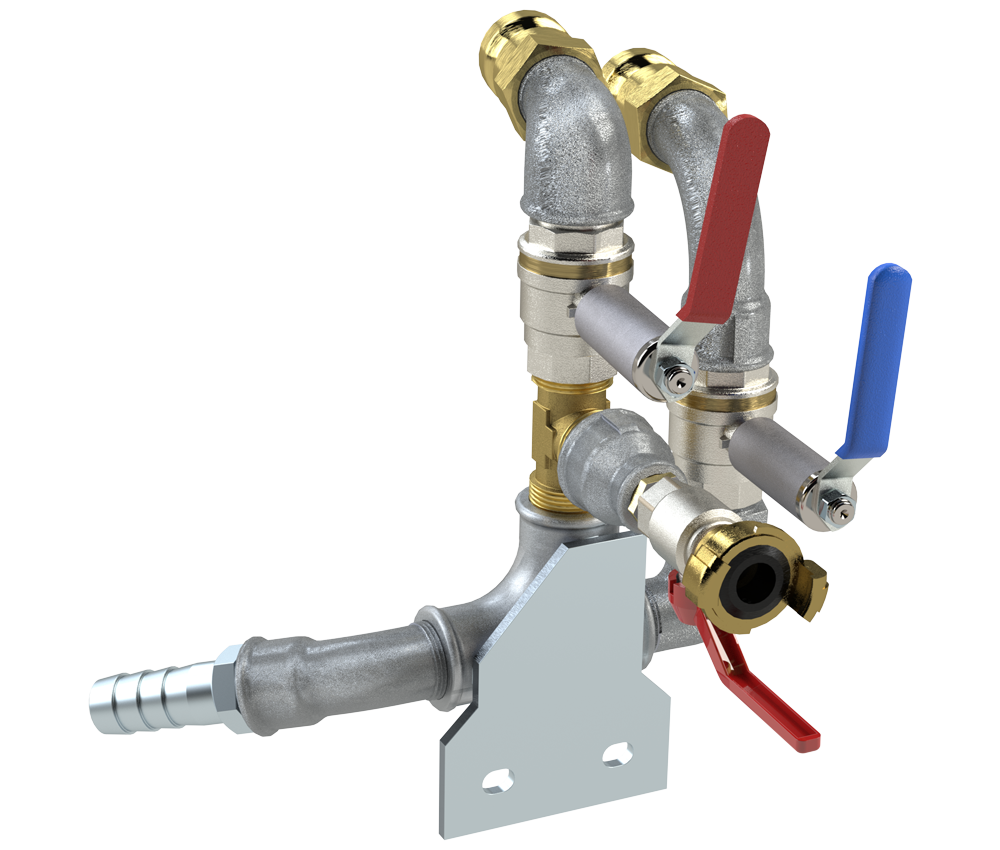

AIR DISTRIBUTOR VALVE

Customized, ready-to-install unit for distributing process air in construction machinery.

- High temperature resistance

- Robust design

Distribution of process air in construction machinery.

PRODUCTS USED

COMPRESSED AIR TECHNOLOGY IN CONSTRUCTION VEHICLE MANUFACTURING

In construction vehicle manufacturing, various products of compressed air technology are employed, playing a significant role in this industry. Compressed air serves as a vital energy source, utilized for diverse functions and applications in the construction sector. Below are some examples of compressed air technology products used in construction vehicle manufacturing:

1. AIR COMPRESSORS:

Construction vehicles are often equipped with integrated compressed air compressors. These compressors generate compressed air on-site, enabling the use of pneumatic tools and equipment directly at the construction site. Pneumatic tools such as jackhammers, drills, and nail guns are operated using compressed air.

2. PNEUMATIC BRAKES:

Heavy construction vehicles like excavators and bulldozers may be equipped with pneumatic brake systems. These systems provide reliable and powerful braking performance, crucial for safety on construction sites.

3. PNEUMATIC LIFTING AND TIPPING DEVICES:

Construction vehicles such as dump trucks and cranes often utilize pneumatic systems to lift, lower, or tilt loads. These systems enable the efficient movement and positioning of heavy materials.

4. PNEUMATIC TIRE PRESSURE REGULATION SYSTEMS:

Some construction vehicles are equipped with pneumatic tire pressure regulation systems. These systems allow drivers to adjust tire pressure as needed to optimize traction and performance for varying construction site conditions.

5. PNEUMATIC SUSPENSION SYSTEMS:

Heavy construction vehicles, especially off-road and terrain vehicles, may utilize pneumatic suspension systems. These systems allow for adjustment of the vehicle's height and provide better traction on uneven terrain.

6. PNEUMATIC DRILLING RIGS:

For construction projects requiring drilling, pneumatic drilling rigs are employed. These systems use compressed air to operate drills or drill rods, penetrating rock or soil.

7. PNEUMATIC DUST REMOVAL SYSTEMS:

Construction vehicles equipped with demolition or cutting tools utilize pneumatic dust removal systems to minimize generated dust and debris, improving air quality for operators.

Compressed air technology plays a significant role in construction vehicle manufacturing, serving as an efficient and versatile energy source for many tasks on the construction site. Pneumatic components contribute to the efficiency and performance of construction vehicles and are crucial for the smooth operation of construction projects.

You are interested in a solution for your company?

GET IN TOUCH

Technical services

engineering(at)riegler.de

Phone: 07125 9497-642